Once Through Steam Generators

Once Through Steam Generators (OTSGs) Offshore production units rely on gas turbines to generate most of their electrical power. By deploying a combined cycle gas turbine (CCGT) solution that is tailored to the constraints of offshore installation the electrical output per unit of fuel consumption can be increased by as much as 50%. The latest generation of FPSOs utilise CCGTs to lower the CO2 footprint of operation.

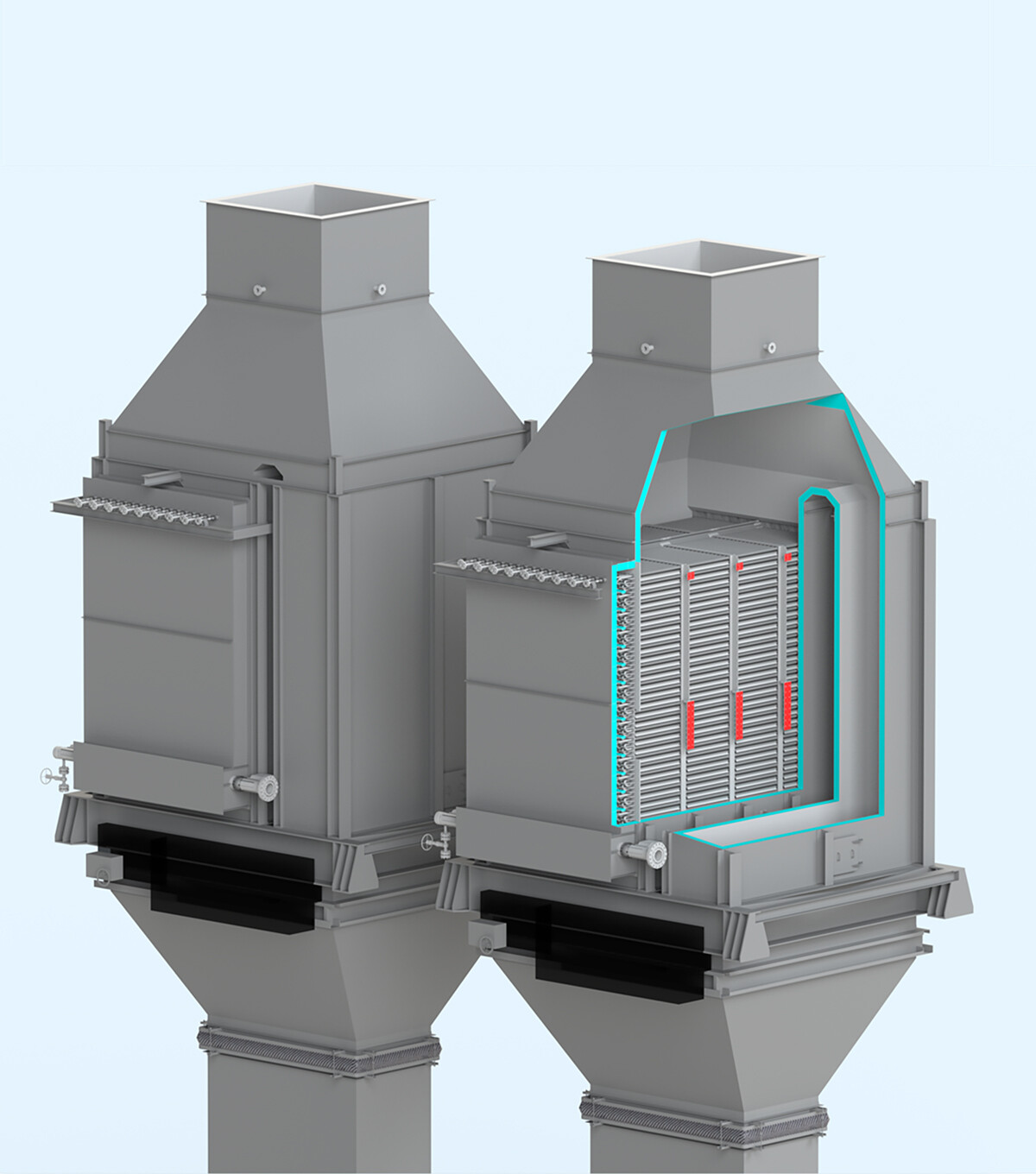

BIH have developed a Once Through Steam Generation (OTSG) solution in which high pressure, high purity steam is generated from the turbine exhaust gases and despatched to a steam turbine.

OTSGs are lighter and more compact than conventional HRSGs and are a drumless solution that is perfectly suited to the constraints of offshore installation. Without the thermal mass of the steam drum the start-up and shut-down times are much shorter compared with those of drum-based HRSGs and therefore more suited to the frequent cycling that may be encountered in offshore applications.

Benefits of OTSGs are:

- Faster response time due to inherent low thermal mass of OTSGs

- High operating flexibility – cold start-up in conjunction with Gas Turbine (GT) start or hot start-up with GT already in operation

- High metallurgy coils contributing to reduced weight, high corrosion resistance and greater resistance to the fatigue effects associated with thermal cycling and continuous dry-run capability

- No boiler blowdown required

- Simplified control scheme compared with conventional HRSGs

Further advantages include:

- Integral exhaust gas bypass system enables greater capacity control and increases operating flexibility

- Possibility to design with multiple pressure levels and/or utility heating

- Vertical exhaust gas flow arrangement reducing the footprint of the unit

- OTSGs are essentially maintenance free with operating runtimes dictated by Gas Turbine maintenance schedules

- Shorter construction time due to modular design and no need for interconnecting boiler piping

- BIH has developed designs to overcome known issues around flow stability

OTSGs can be offered for onshore applications but the more stringent water quality needed compared to drum-based HRSGs mean that they are better suited for heat recovery where higher steam parameters and reduced footprint is required.

Reformers

Direct Fired Heaters

BIH’s team have been designing, supplying and installing fired heaters worldwide for over 40 years. This original product line remains an important cornerstone of the business.

WHRUs

HRSGs

Modularisation